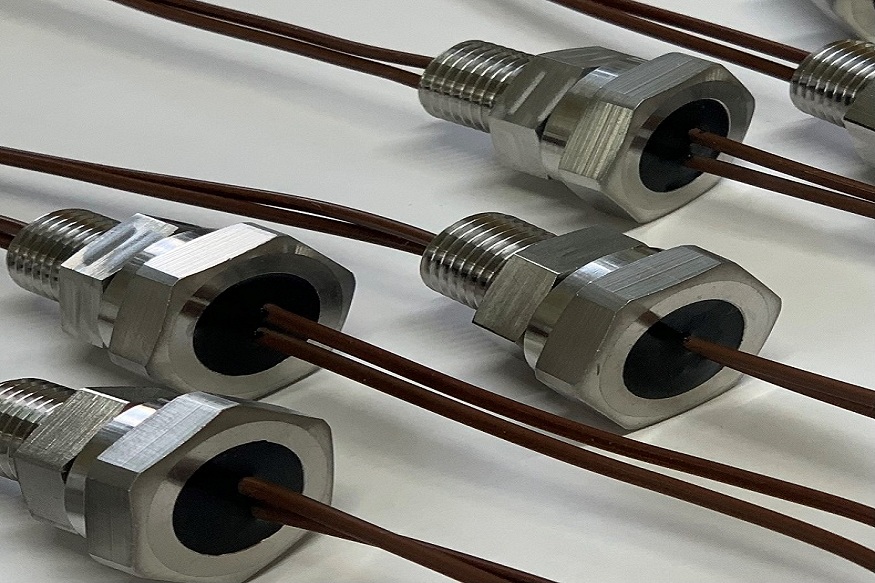

Hermetic feedthroughs are essential components in systems that require sealed electrical, optical, or fluid connections. Standard feedthroughs may meet the needs of many applications, but challenging environments—such as extreme temperatures, high pressure, corrosive atmospheres, or vibration-heavy conditions—often require custom hermetic feedthrough solutions. These tailored designs ensure reliable performance, environmental protection, and long-term durability in critical industrial, aerospace, medical, and scientific applications.

Understanding Challenging Environments

Challenging environments place significant demands on hermetic feedthrough. Factors that can compromise standard feedthroughs include:

- Extreme temperatures (cryogenic or high heat)

- High-pressure or vacuum conditions

- Exposure to corrosive chemicals, humidity, or saltwater

- Mechanical stress, vibration, or shock

- High-voltage or high-frequency signals

Custom feedthroughs are designed to address these conditions by selecting the right materials, design, and sealing techniques for each application.

Materials for Custom Hermetic Feedthroughs

The choice of materials is a critical factor in designing feedthroughs for challenging environments:

- Ceramics: Alumina and other engineered ceramics provide excellent thermal stability, electrical insulation, and mechanical strength.

- Glass: Borosilicate or specialty glasses maintain vacuum sealing and dielectric performance.

- Metals: Stainless steel, titanium, and Kovar alloys ensure structural integrity, corrosion resistance, and thermal expansion compatibility.

- Coatings and sealants: Protective coatings enhance chemical resistance and longevity in harsh conditions.

Material selection is tailored to match the specific environmental challenges and operational requirements of each application.

Custom Designs for Extreme Conditions

Custom hermetic feedthroughs can be engineered to meet unique operational needs:

- High-temperature designs: Use ceramics and high-melting-point metals to maintain seals in furnaces, engines, or industrial heaters.

- High-pressure solutions: Reinforced housings and welding techniques prevent leaks in deep-sea or high-pressure industrial systems.

- Vibration-resistant feedthroughs: Special mounting, flexible pins, and shock-resistant materials ensure reliability in aerospace or heavy machinery.

- Multi-pin and high-density configurations: Provide multiple connections through a single sealed barrier for compact systems and complex instrumentation.

These designs ensure that feedthroughs remain functional and reliable even in the most extreme conditions.

Applications in Aerospace and Defense

Aerospace and defense industries require feedthroughs that can withstand temperature extremes, vibration, and pressurization:

- Satellites and spacecraft rely on hermetic feedthroughs for electrical and RF connections without compromising vacuum or thermal conditions.

- Military avionics use multi-pin, vibration-resistant feedthroughs to maintain operational integrity in harsh environments.

- Radar and communication systems benefit from high-frequency, hermetically sealed coaxial feedthroughs.

Custom solutions ensure mission-critical reliability in these high-stakes applications.

Applications in Medical Devices

Medical technology often demands miniaturized, high-performance, and sterilizable feedthroughs:

- Implantable devices, such as pacemakers and neural stimulators, require biocompatible, hermetic seals to prevent contamination and fluid ingress.

- Imaging systems, including MRI and CT scanners, use custom feedthroughs to transmit high-frequency signals while maintaining vacuum or cryogenic cooling.

- Surgical instruments incorporate custom multi-pin feedthroughs to ensure precise sensor and control functionality.

Custom designs ensure patient safety, regulatory compliance, and device longevity.

Industrial and Scientific Applications

Industrial and research environments often present unique challenges:

- Vacuum chambers and semiconductor equipment: Require feedthroughs that maintain ultra-high vacuum while transmitting electrical signals.

- Chemical processing plants: Use chemically resistant feedthroughs that prevent corrosion and maintain sealing under harsh exposure.

- Cryogenic research and particle accelerators: Depend on specialized materials and sealing methods to function reliably at extreme temperatures.

Custom solutions address these challenges by combining material science, engineering, and advanced sealing techniques.

Advantages of Custom Hermetic Feedthroughs

Custom feedthroughs provide significant benefits over standard designs:

- Enhanced reliability: Engineered to withstand specific environmental stresses.

- Optimized performance: Tailored to the operational requirements of voltage, current, signal frequency, and pressure.

- Longevity: Designed to minimize maintenance and prevent premature failure.

- Space and efficiency: Multi-pin or high-density configurations reduce complexity in compact systems.

- Safety and compliance: Meets stringent industrial, aerospace, or medical standards.

By choosing a custom solution, organizations can achieve maximum performance in environments where standard feedthroughs would fail.

Conclusion

Hermetic feedthroughs are indispensable for maintaining environmental integrity and reliable connections in critical systems. In challenging environments, custom feedthrough solutions provide the materials, design, and sealing techniques necessary to handle extreme temperatures, pressure, vibration, chemical exposure, and complex signal requirements. Whether in aerospace, medical devices, industrial systems, or scientific research, custom hermetic feedthroughs ensure reliability, safety, and long-term performance.

Investing in a custom solution ensures that your systems operate flawlessly even under the most demanding conditions, protecting sensitive equipment and maintaining operational integrity in high-stakes applications.